Products

MRP-II / ERP

Manufacturing & Distribution

Manufacturing & Distribution

Process Control

The Process Order module comprises

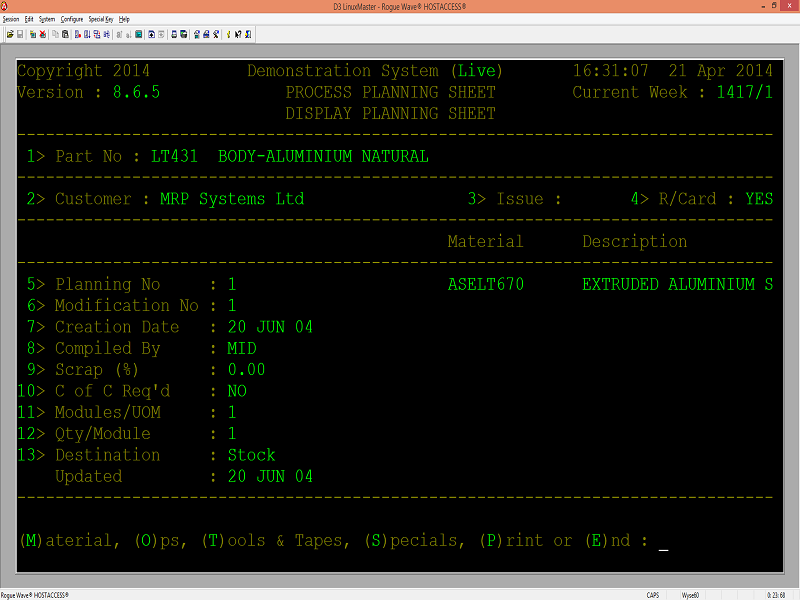

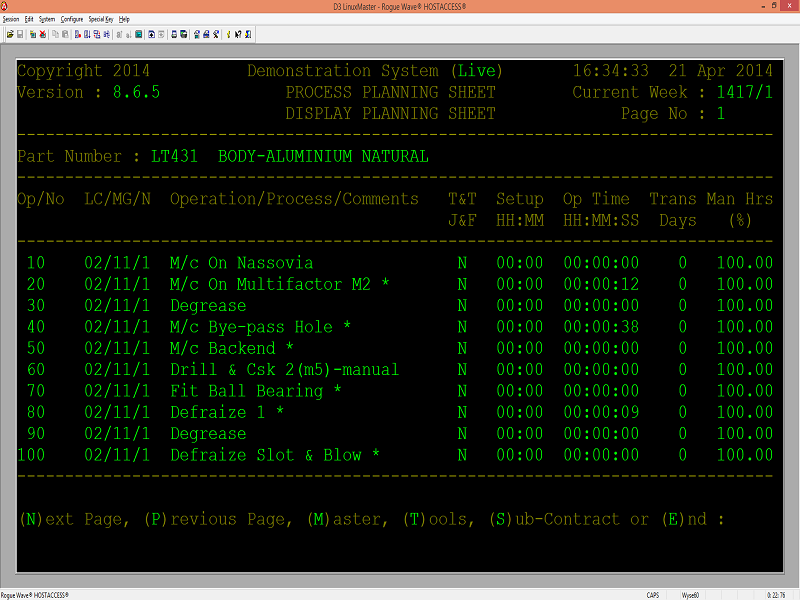

Planning / Method Sheets

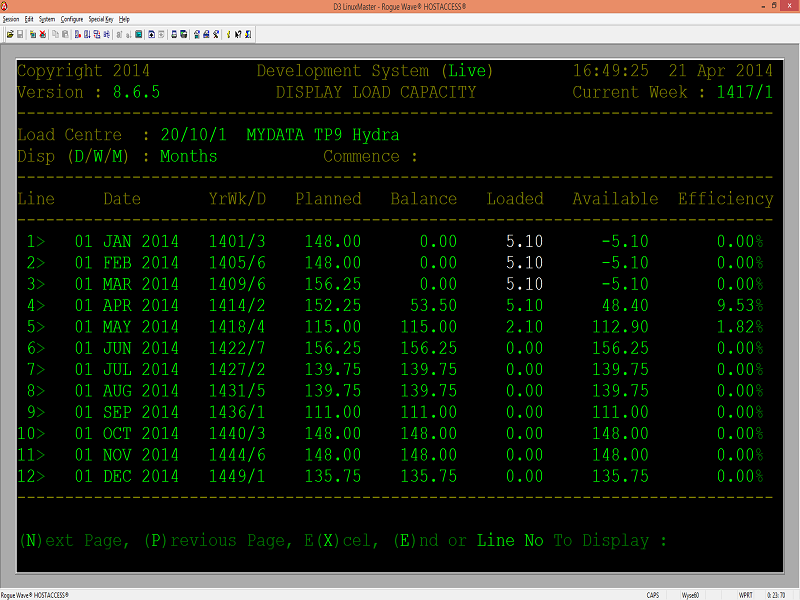

Load Centres

Routing File / Capacity Planning

Reporting

Planning Sheets

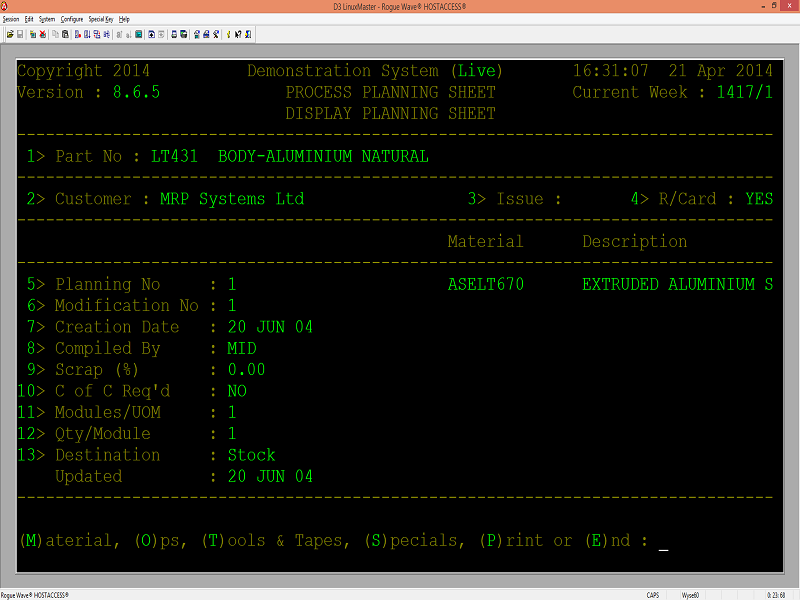

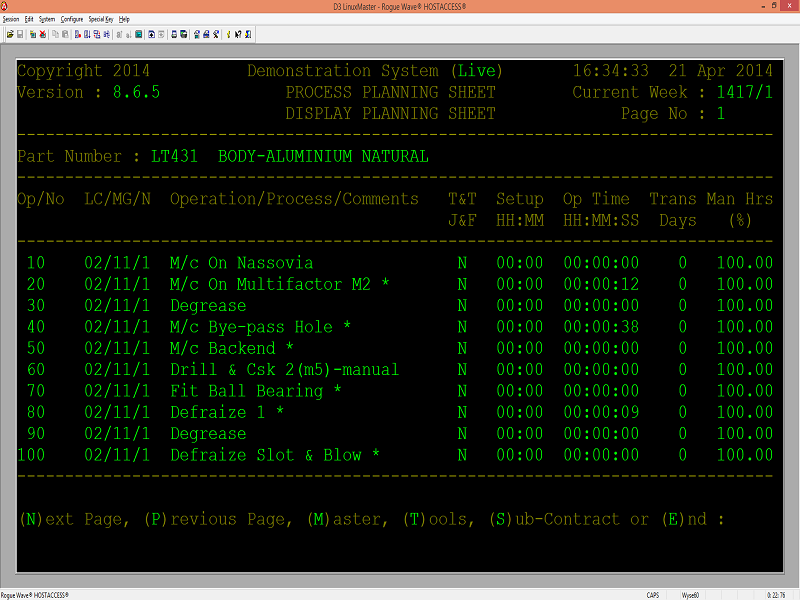

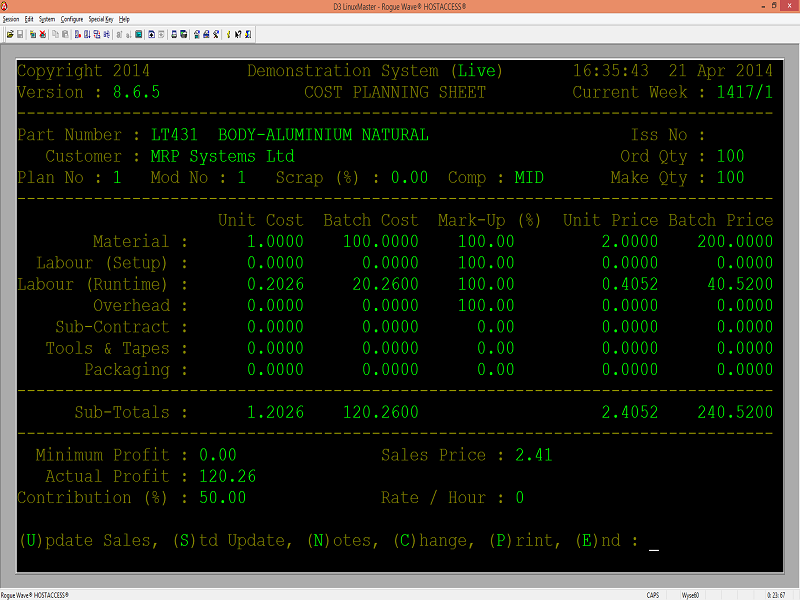

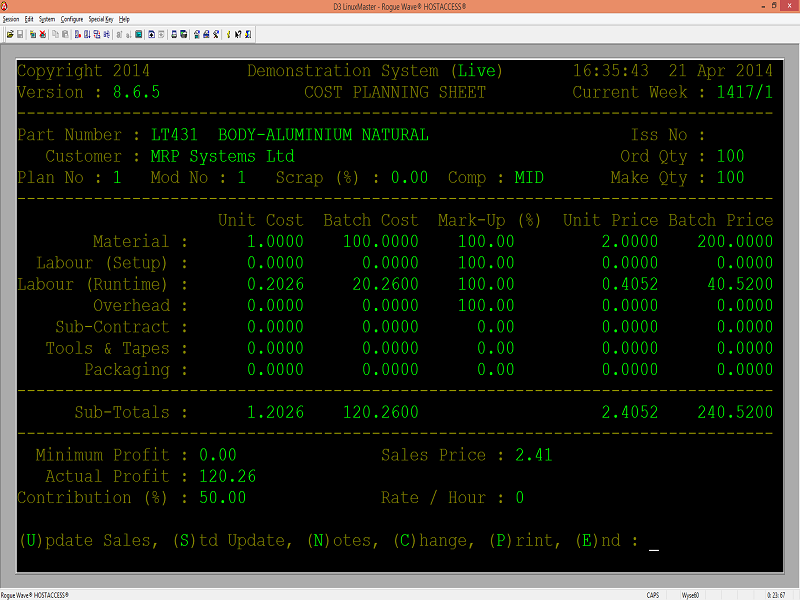

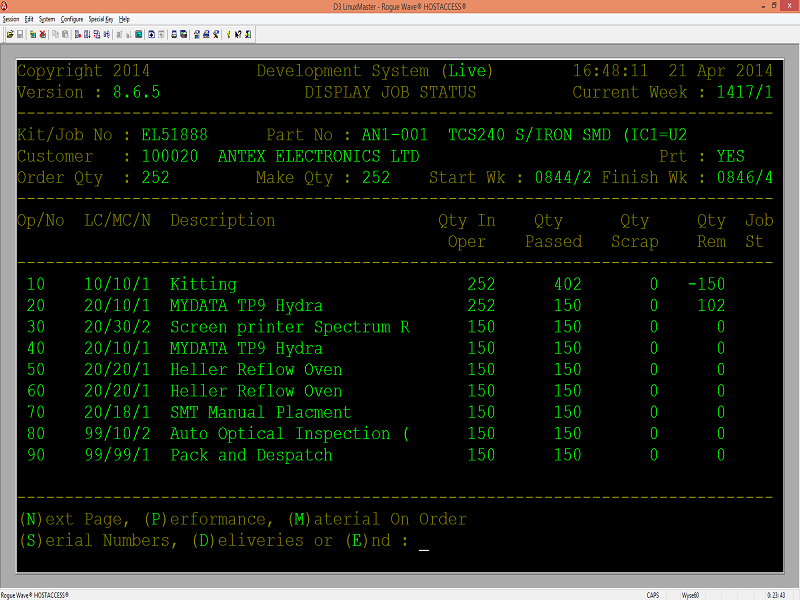

The Process Control module extends the Works Orders into a much more detailed "work in progress". Apart from having a "dues-in" of the Parent, and the "dues-out" for the Components, you can create a Method Sheet detailing exactly how a product is made, broken down into a series of operations, going via specific Work/Load Centres. This method sheet can have "times" applied to it to (a) provide an accurate Assembly Cost (in terms of Labour), and (b) a dynamic LEAD TIME based upon batch size for jobs to start and finish. Hook into this a Capacity Calendar and the MRP application can produce a planning schedule based on either "finite" or "infinite" rules. Method & Modification control can be utilised to keep a track of "issue" change, or simply that you have completely different approaches to making the same assembly

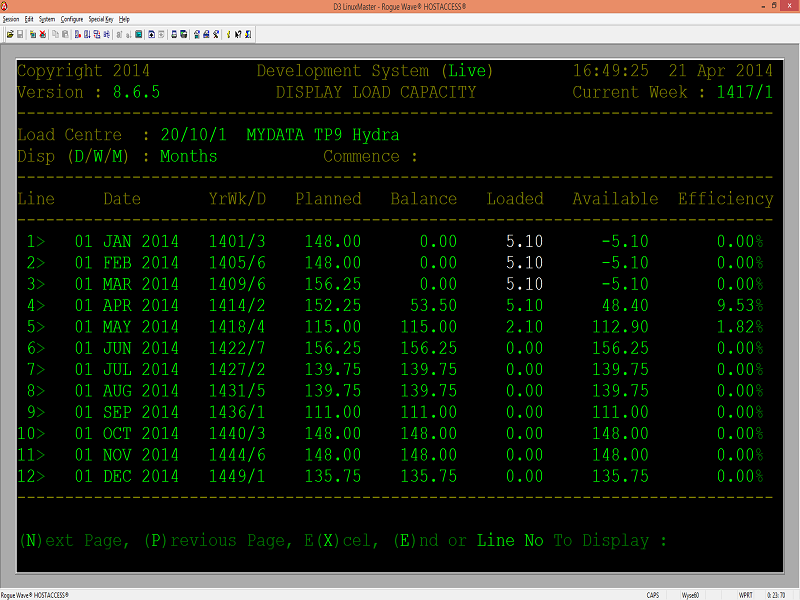

Load Centres

Pre-defined work centres that your product will pass through to arrive at the completed item. For example, Pick & Place, Flow Solder, CNC Machine, Paint Shop, Manual Assembly, Silk Screening, Packing etc. Each Load Centre can have "Rates" applied (ie Rate / Hour) for Machine & Manual Setup, Machine & Manual Runtime, Overhead and Sub-Contract. These profiles interact with Assembly Valuation and Capacity Planning.

Routing File / Capacity Planning

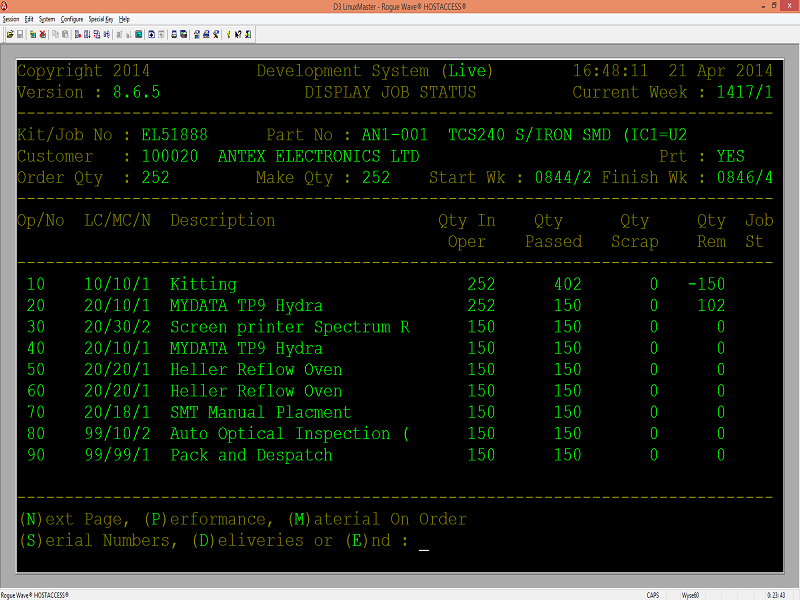

As jobs are raised on the system a routing record is generated so not only are you "aware" that a job is in progress, but exactly where that job is on the production line. TimeSheets enable the recording of the job through the shop floor and/or times taken to do the work. Back Flushing is optional so that you can miss operational steps out if required.

Reporting

Outstanding Jobs By Customer / Date / Part, Load Centre Capacity Report, Customer Progress Analysis, Scrap Analysis, Time Booked, Job Performance, Employee Attendance are just a handful of the facilities available (either PDF or EXCEL)

The Process Order module comprises

Planning / Method Sheets

Load Centres

Routing File / Capacity Planning

Reporting

Planning Sheets

The Process Control module extends the Works Orders into a much more detailed "work in progress". Apart from having a "dues-in" of the Parent, and the "dues-out" for the Components, you can create a Method Sheet detailing exactly how a product is made, broken down into a series of operations, going via specific Work/Load Centres. This method sheet can have "times" applied to it to (a) provide an accurate Assembly Cost (in terms of Labour), and (b) a dynamic LEAD TIME based upon batch size for jobs to start and finish. Hook into this a Capacity Calendar and the MRP application can produce a planning schedule based on either "finite" or "infinite" rules. Method & Modification control can be utilised to keep a track of "issue" change, or simply that you have completely different approaches to making the same assembly

Load Centres

Pre-defined work centres that your product will pass through to arrive at the completed item. For example, Pick & Place, Flow Solder, CNC Machine, Paint Shop, Manual Assembly, Silk Screening, Packing etc. Each Load Centre can have "Rates" applied (ie Rate / Hour) for Machine & Manual Setup, Machine & Manual Runtime, Overhead and Sub-Contract. These profiles interact with Assembly Valuation and Capacity Planning.

Routing File / Capacity Planning

As jobs are raised on the system a routing record is generated so not only are you "aware" that a job is in progress, but exactly where that job is on the production line. TimeSheets enable the recording of the job through the shop floor and/or times taken to do the work. Back Flushing is optional so that you can miss operational steps out if required.

Reporting

Outstanding Jobs By Customer / Date / Part, Load Centre Capacity Report, Customer Progress Analysis, Scrap Analysis, Time Booked, Job Performance, Employee Attendance are just a handful of the facilities available (either PDF or EXCEL)