Products

MRP-II / ERP

Manufacturing & Distribution

Manufacturing & Distribution

Reservations / Works Orders

The Reservations module holds the following files

Single Level Reservations

Multi-Level Reservations

Single Line Additions (SLA's)

Free Stock Analysis

Reporting

Single / Multi-Level reservations

All works orders can be input manually by the user (or automated from other modules within MRP). The system raises the necessary Works Order (ie DUES-IN) of the Parent Part, whilst creating the DUES-OUT demand for all the component parts (from the BOM record). Net-Stock balance can be interjected or ignored at point of creation / update. Lead Times held within the Inventory module will determine START / FINISH dates date of Jobs (or calculated from Planning Sheets / Capacity module if utilised)

SLA's (Single Line Additions) allows extra items to be linked to a JOB if required. Useful tool for either setting up extra demand for components, over and above MRP demand, or simply adding extra items to an existing job, because parts had been missed off the BOM record (or superseded)

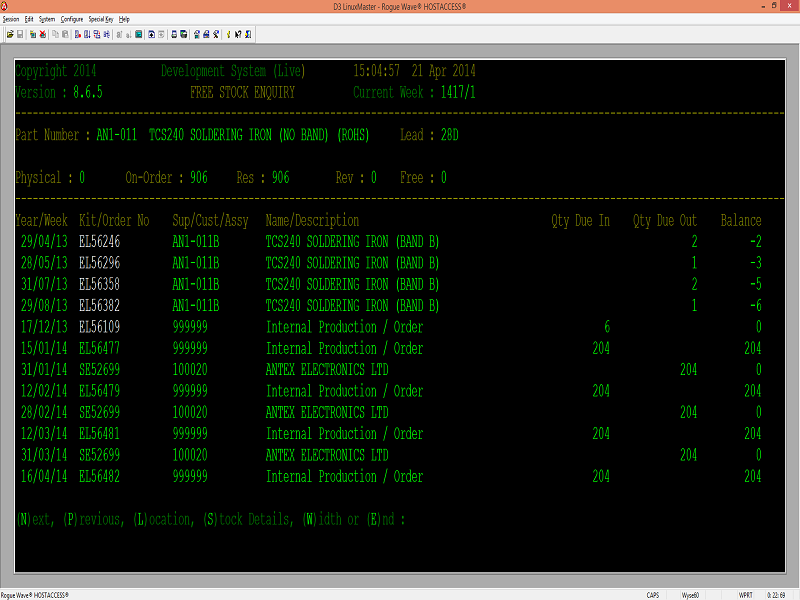

Free Stock Analysis

Real-Time stock screen showing all "dues-in" and "dues-out" in regards to Sales Orders, Purchase Orders and Manufacturing process.

Reporting

Free Stock Reporting, Exceptions, Ghost Kitting, Re-Scheduling, Order Imbalance, Over-Stocking and Production Summary are just a handful of the facilities available (either PDF or EXCEL)

The Reservations module holds the following files

Single Level Reservations

Multi-Level Reservations

Single Line Additions (SLA's)

Free Stock Analysis

Reporting

Single / Multi-Level reservations

All works orders can be input manually by the user (or automated from other modules within MRP). The system raises the necessary Works Order (ie DUES-IN) of the Parent Part, whilst creating the DUES-OUT demand for all the component parts (from the BOM record). Net-Stock balance can be interjected or ignored at point of creation / update. Lead Times held within the Inventory module will determine START / FINISH dates date of Jobs (or calculated from Planning Sheets / Capacity module if utilised)

SLA's (Single Line Additions) allows extra items to be linked to a JOB if required. Useful tool for either setting up extra demand for components, over and above MRP demand, or simply adding extra items to an existing job, because parts had been missed off the BOM record (or superseded)

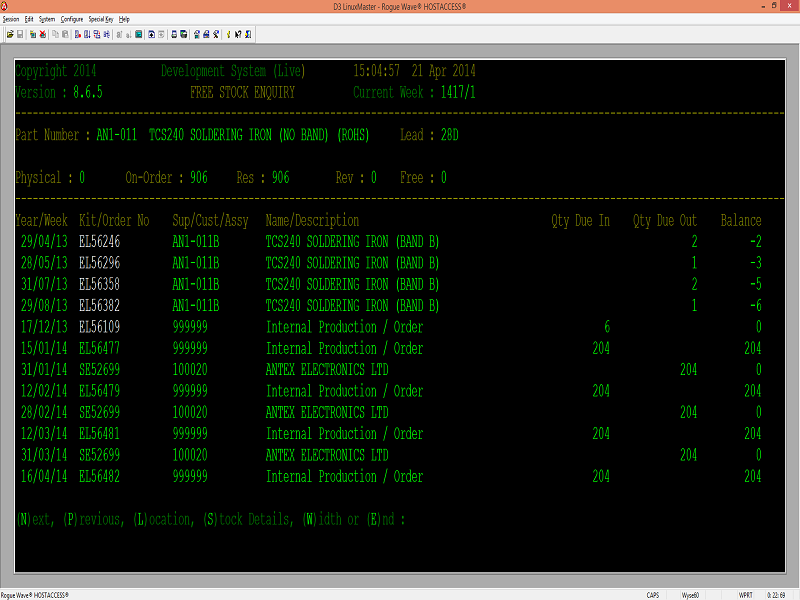

Free Stock Analysis

Real-Time stock screen showing all "dues-in" and "dues-out" in regards to Sales Orders, Purchase Orders and Manufacturing process.

Reporting

Free Stock Reporting, Exceptions, Ghost Kitting, Re-Scheduling, Order Imbalance, Over-Stocking and Production Summary are just a handful of the facilities available (either PDF or EXCEL)