Products

MRP-II / ERP

Manufacturing & Distribution

Manufacturing & Distribution

Purchase Order Processing / GRN

The Purchase Order module comprises

Purchase Orders

Automatic Re-Ordering

Goods Received

Goods Inspection

Buying Cards

Reporting

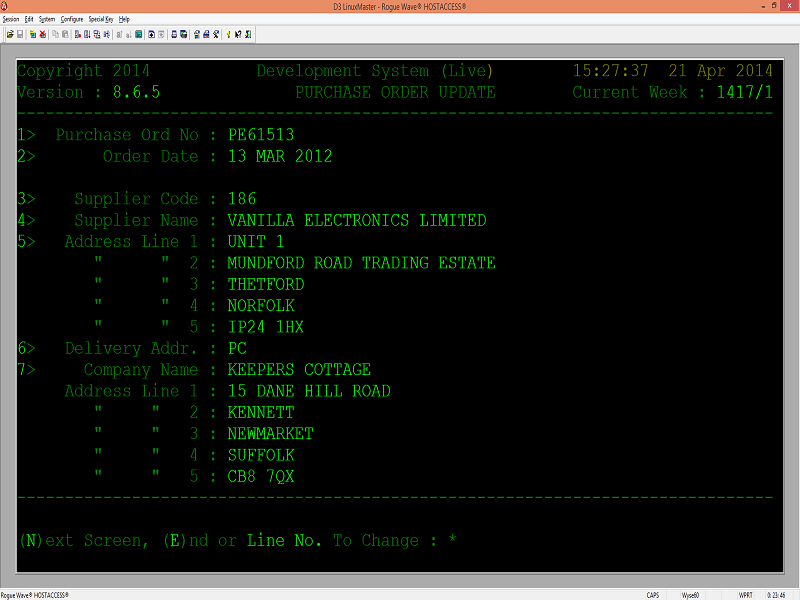

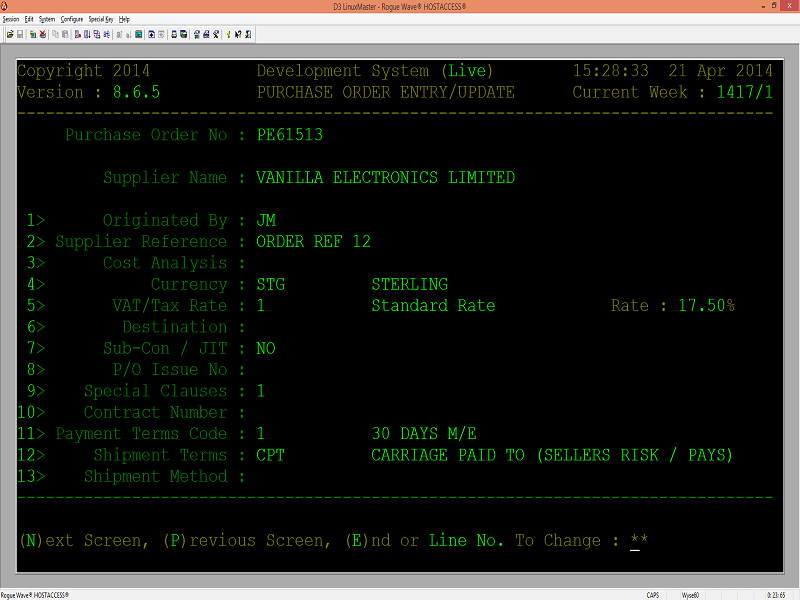

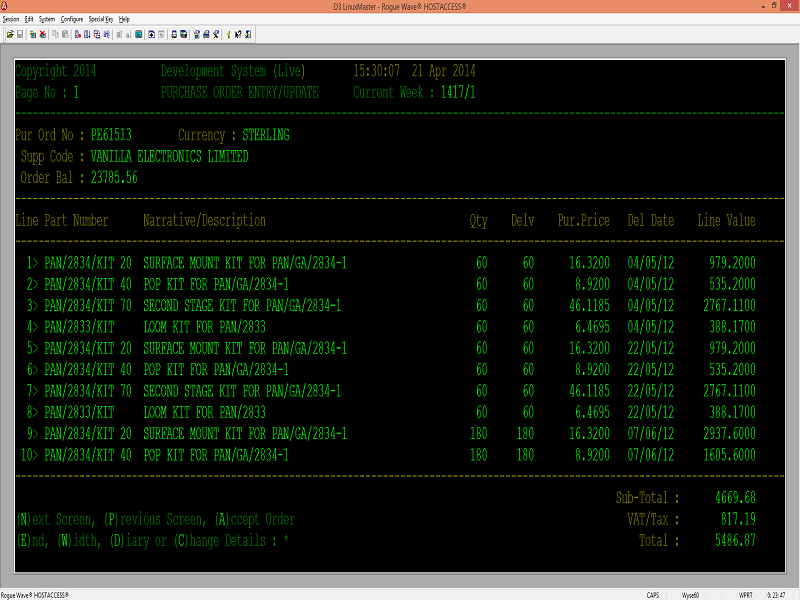

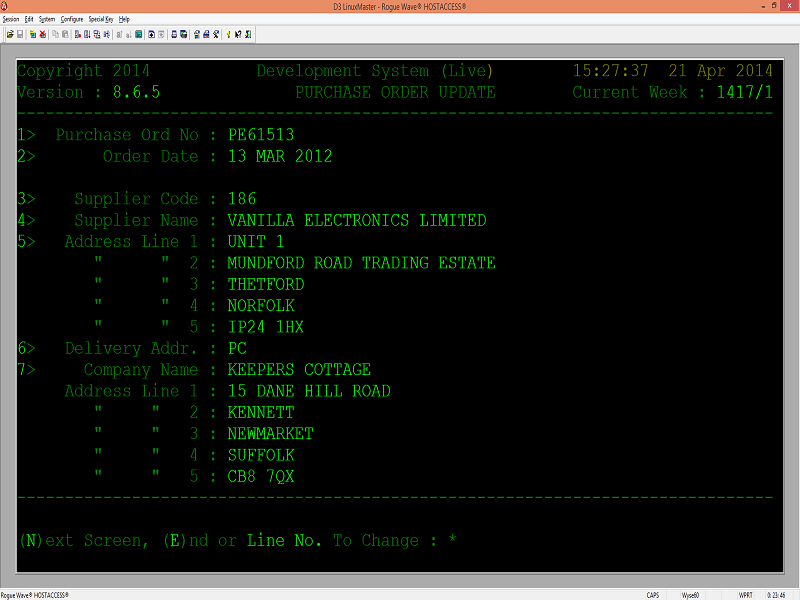

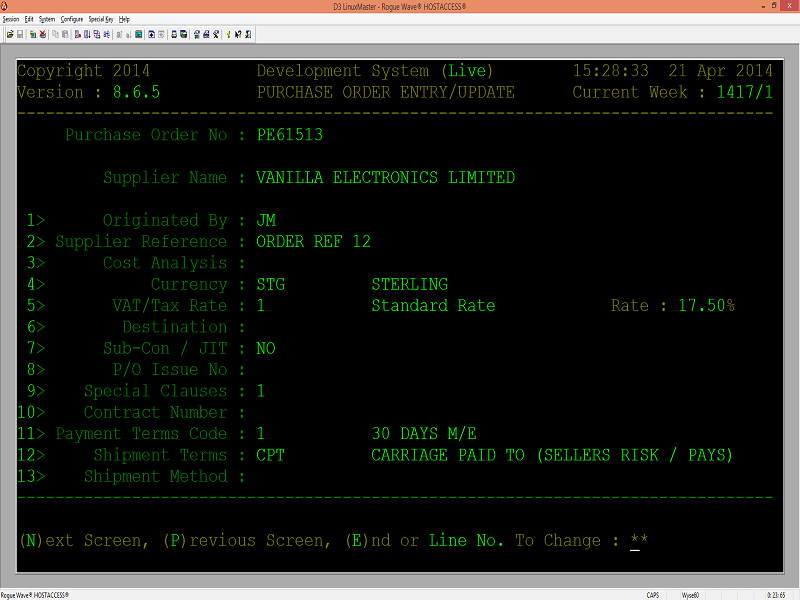

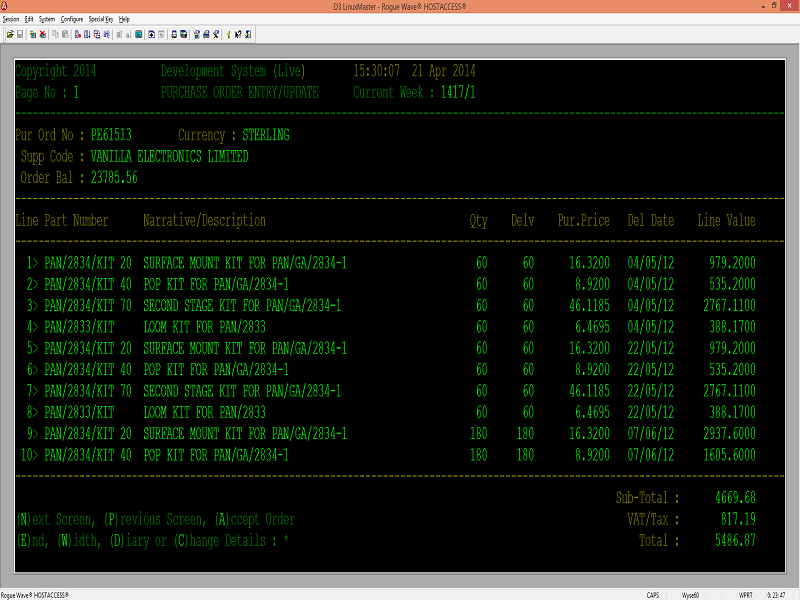

Purchase Orders

Standard P/O entry system to enable the user to raise orders on suppliers. Maximum of 200 line items per order with the facility to schedule as far ahead as you wish. Interactive Buying Card / Supplier Part references can be cross referenced on Purchase Order. Support for Special Supplier Prices, and Price Matrix tables. Support for Sub-Contract P/O along with JIT / KanBan

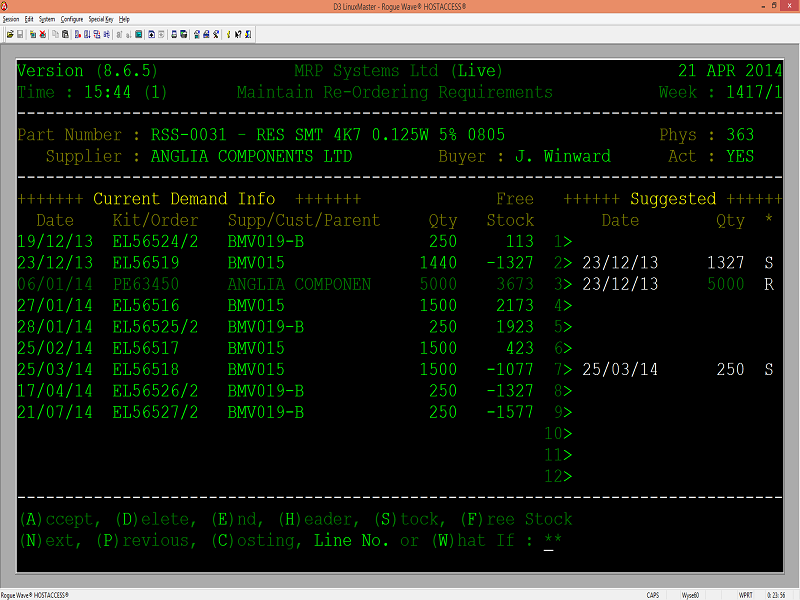

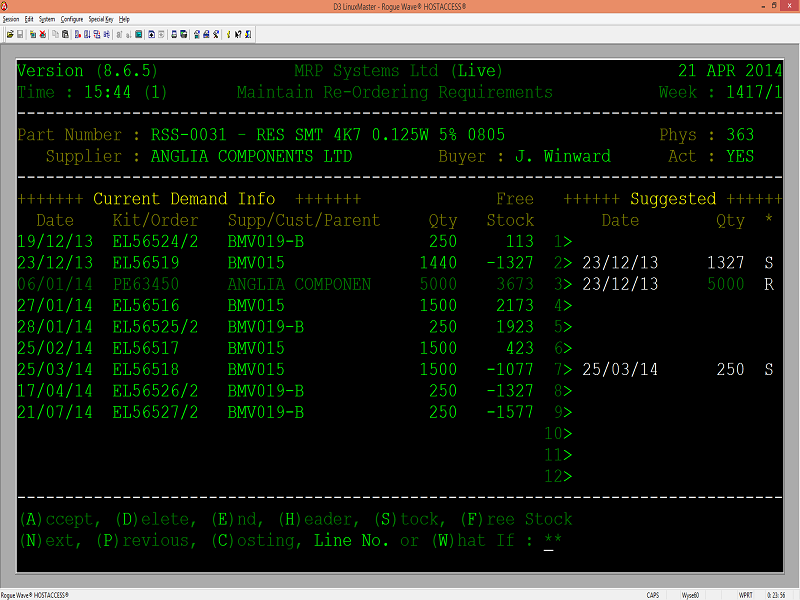

Automatic Re-Ordering

The MRP application can automatically scan the Free Stock screen and produce a Suggested P/O List. This "suggested" list is a comination of NEW orders required and RE-SCHEDULE orders already on the system. This takes into account Preferred Suppliers, Last Supplier Used, Lead Times, Dock-To-Stock, Minimum Order Qty's, EBQ's, Supplier shutdown periods and so forth. The module is interactive for the userrs, in that you produce the Suggested Ordering, and then it allows you to tailor any individual Supplier / Part before generation. Once happy with the user intervention, a simple press of a button and all purchase orders will be raised, along with existing orders updated.

Goods Received / Inspection

All goods booked into stock can be done so, either direct to stores or via a Goods-In Inspection module. Inspection Module is controlled on a Global Parameter, or on a part by part basis. Qty Advised, Qty Delivered and Qty Accepted are held for each GRN and GRN's can be propduced per delivery or per line, per delivery. Discrepancy Reporting and Reject Analysis are standard features. Automatic Reject Notes can be produced (along with DEBIT NOTES for Purchase Ledger if necessary).

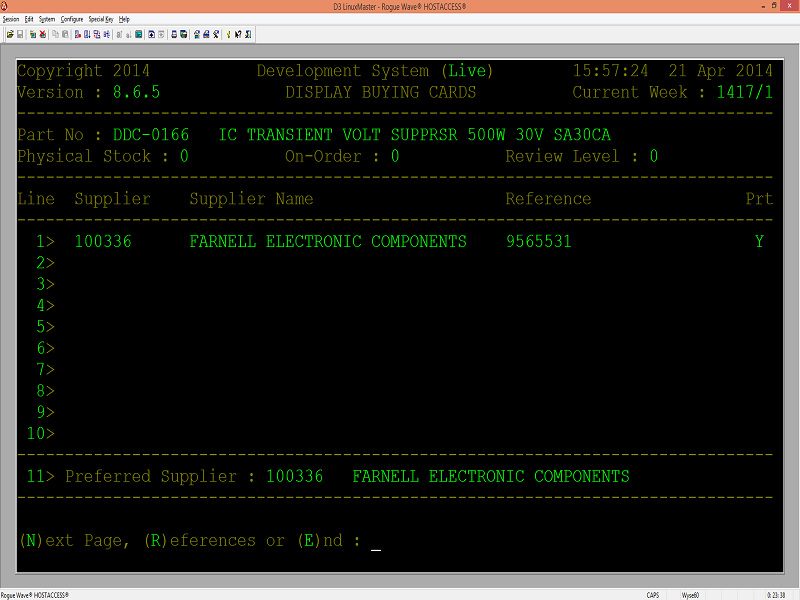

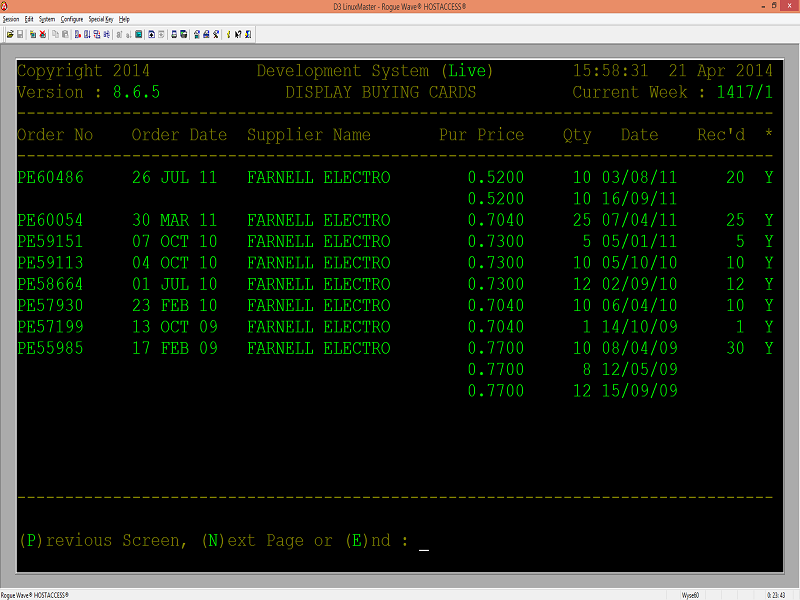

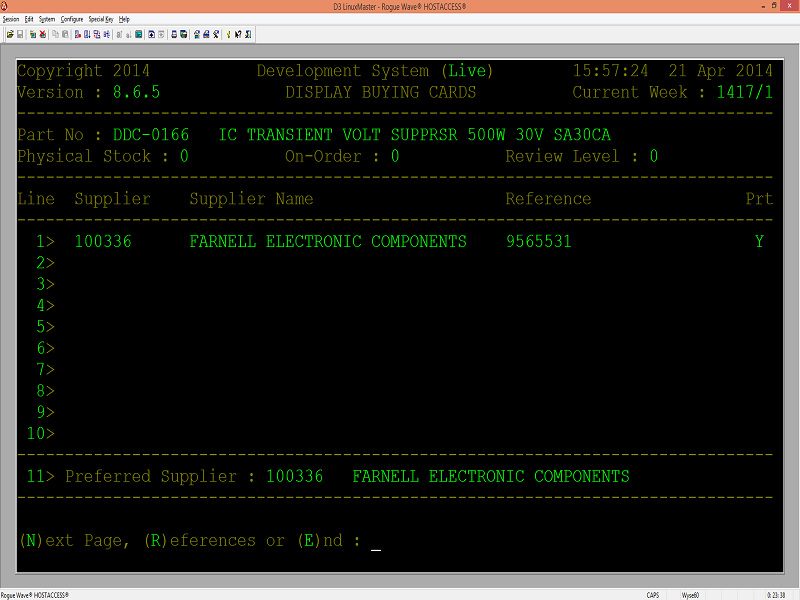

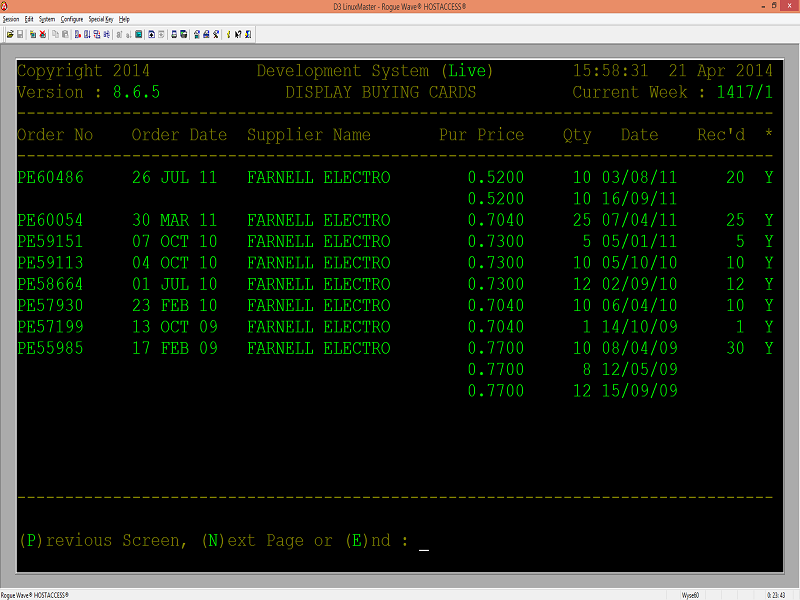

Buying Cards

Traditional cardex system that most Buyers are familiar with. Facility to store up to 10 suppliers per part, along with Supplier Reference and also 10 manufacturers per Supplier, along with their references. You can assign a "Prefereed Supplier" for integration to automatic P/O generation. All previous buying history for a part and prices paid are held within the Buying Card for as long as you wish.

Reporting

Over 50 standard reports within the Purchasing Module covering Buying Cards, Orders and Receipts. Outstanding Orders, Projected Cash Flow, Turnover Analysis, Reject Analysis, Supplier Performance are just a handful of the facilities available (either PDF or EXCEL)

The Purchase Order module comprises

Purchase Orders

Automatic Re-Ordering

Goods Received

Goods Inspection

Buying Cards

Reporting

Purchase Orders

Standard P/O entry system to enable the user to raise orders on suppliers. Maximum of 200 line items per order with the facility to schedule as far ahead as you wish. Interactive Buying Card / Supplier Part references can be cross referenced on Purchase Order. Support for Special Supplier Prices, and Price Matrix tables. Support for Sub-Contract P/O along with JIT / KanBan

Automatic Re-Ordering

The MRP application can automatically scan the Free Stock screen and produce a Suggested P/O List. This "suggested" list is a comination of NEW orders required and RE-SCHEDULE orders already on the system. This takes into account Preferred Suppliers, Last Supplier Used, Lead Times, Dock-To-Stock, Minimum Order Qty's, EBQ's, Supplier shutdown periods and so forth. The module is interactive for the userrs, in that you produce the Suggested Ordering, and then it allows you to tailor any individual Supplier / Part before generation. Once happy with the user intervention, a simple press of a button and all purchase orders will be raised, along with existing orders updated.

Goods Received / Inspection

All goods booked into stock can be done so, either direct to stores or via a Goods-In Inspection module. Inspection Module is controlled on a Global Parameter, or on a part by part basis. Qty Advised, Qty Delivered and Qty Accepted are held for each GRN and GRN's can be propduced per delivery or per line, per delivery. Discrepancy Reporting and Reject Analysis are standard features. Automatic Reject Notes can be produced (along with DEBIT NOTES for Purchase Ledger if necessary).

Buying Cards

Traditional cardex system that most Buyers are familiar with. Facility to store up to 10 suppliers per part, along with Supplier Reference and also 10 manufacturers per Supplier, along with their references. You can assign a "Prefereed Supplier" for integration to automatic P/O generation. All previous buying history for a part and prices paid are held within the Buying Card for as long as you wish.

Reporting

Over 50 standard reports within the Purchasing Module covering Buying Cards, Orders and Receipts. Outstanding Orders, Projected Cash Flow, Turnover Analysis, Reject Analysis, Supplier Performance are just a handful of the facilities available (either PDF or EXCEL)