Products

MRP-II / ERP

Manufacturing & Distribution

Manufacturing & Distribution

Inventory Management

The Inventory Management module holds the following files

Stock Records

Product Groups

Product Families

Classification Codes

Alternative Parts File

Multi-Stock Locations

Reporting

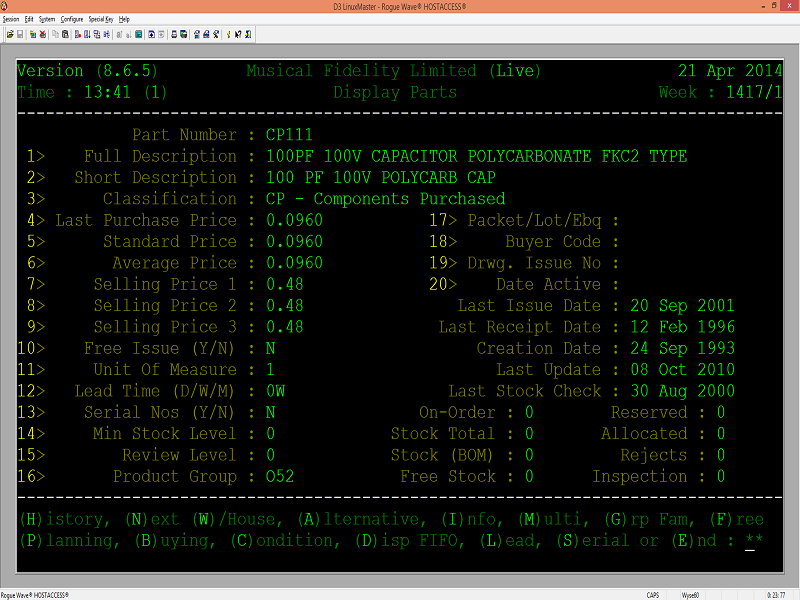

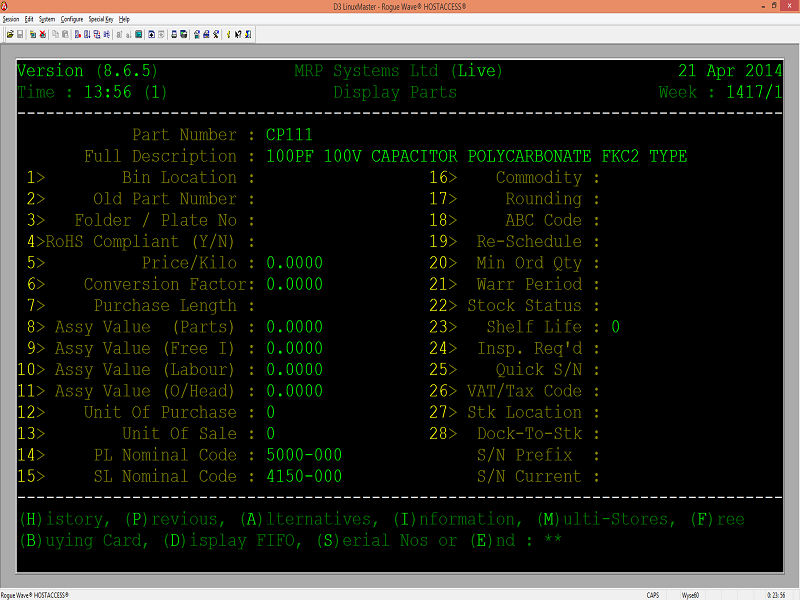

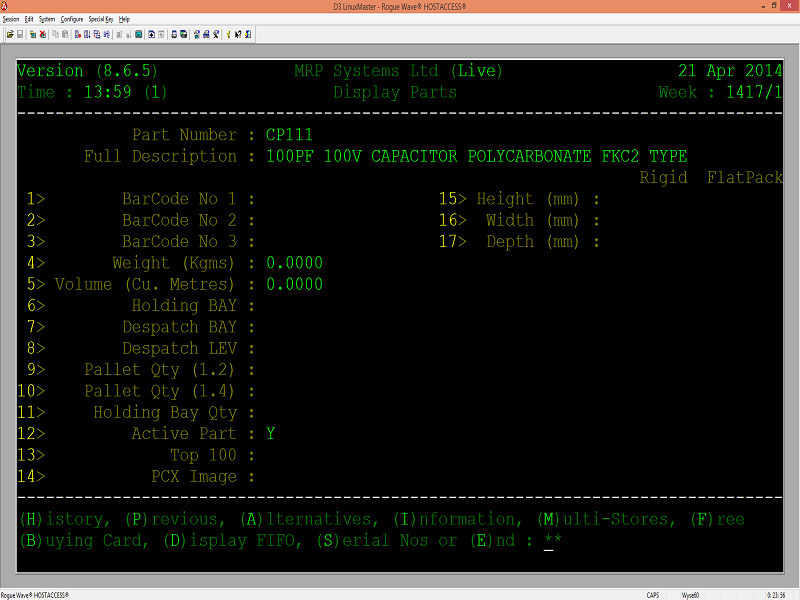

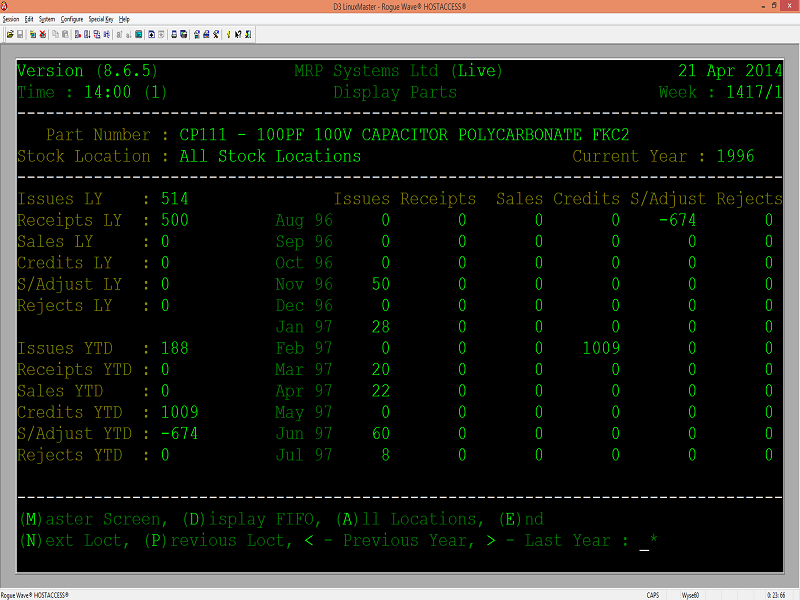

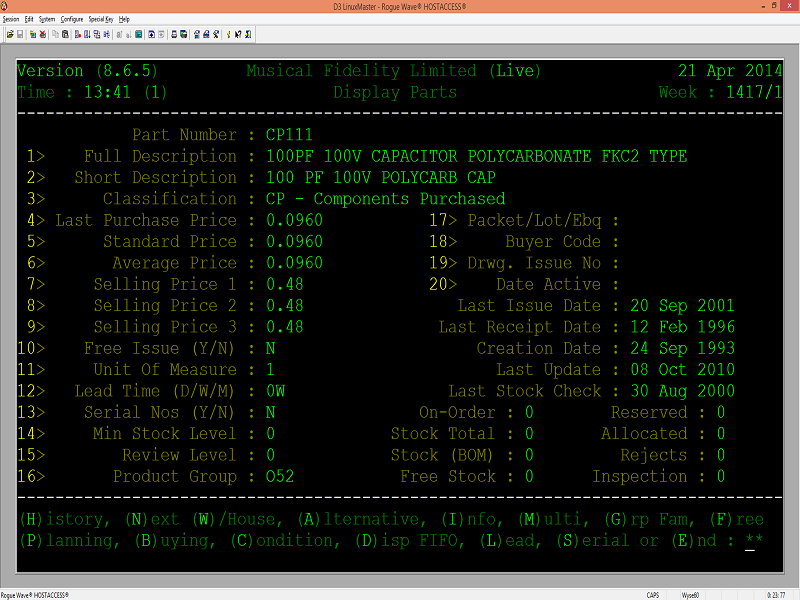

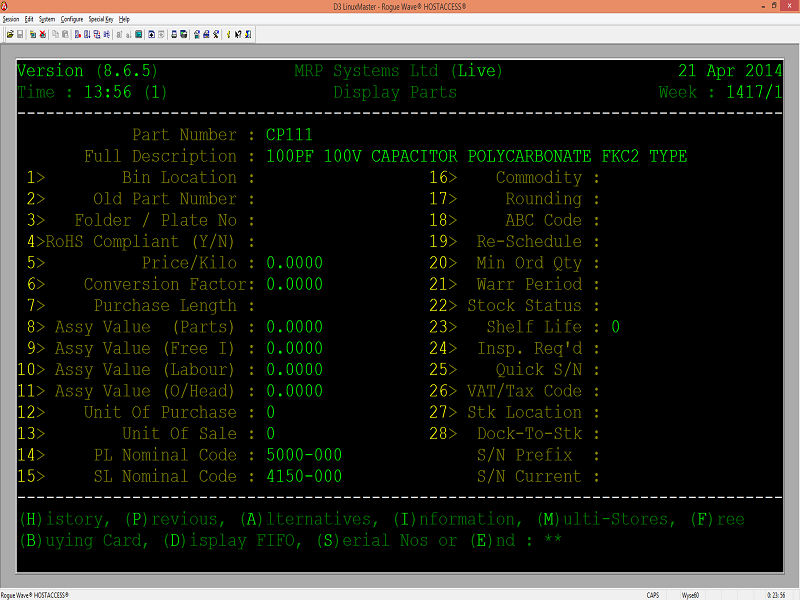

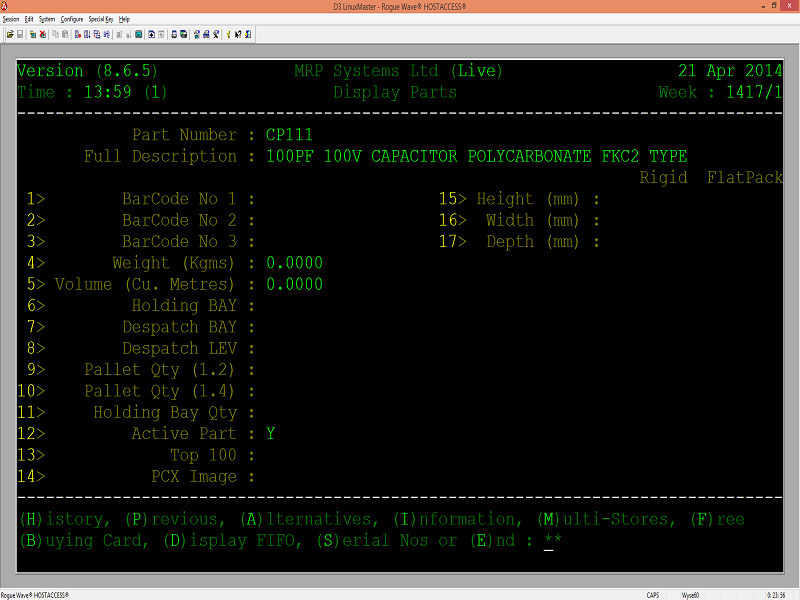

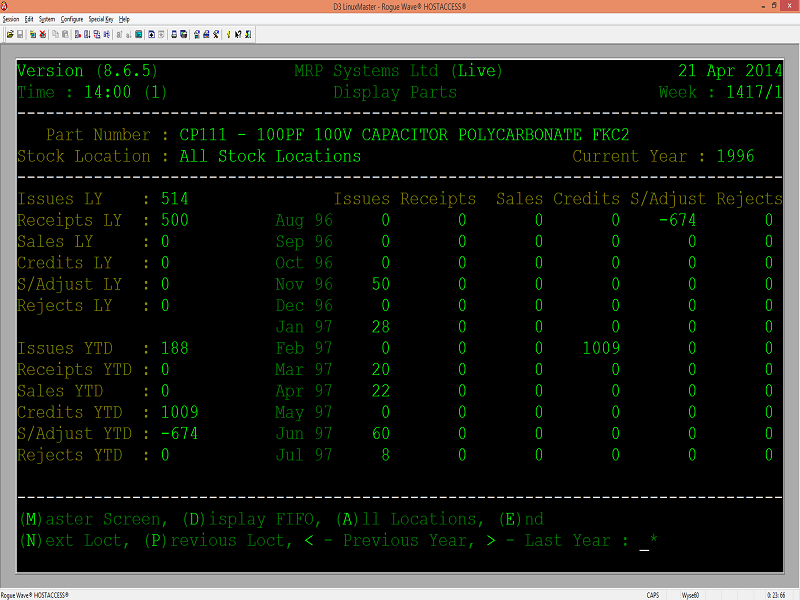

Stock Records

Each part on the system (whether a Parent or Component) holds a vast amount of information that will be used throughout the MRP application if required. We hold Last Purchase Price, Average Price (weighted or simple), Standard Price (for Standard Costing), and initially 3 Selling Prices for use within Sales Order Processing module. Other standard fields are Minimum Order Qty, Review Levels, Minimum Stock Levels, ABC Classification, Weights, Volumes and Dimensions. Packet Sizes, Economic Batch Qty's (for make or order), Drawing Issue Numbers, and Effectivity Date, are just a few.

Due to the vast number of fields available for each stock item, here are some screenshots to assist in trying to outline a majority of those that are available

Product Groups

Because of the large number of part numbers a client may have, these parts can then be "labelled" into Product Groups. Product Groups could be codes like FG - Finished Goods, CMP - Components, or more detailed breakdown such as VAL - Valves, PTC - Patches and so forth. Product Groups are pre-determined by the client, so you can have as many or as little as you require. Once setup, all reporting can be achieved by Part Number or Product Group. The Purchase Order & Sales Order modules also utilise such profiles.

Product Families

Works a little like Product Groups, but become the overruling "parent" Product Group. For example, a Hi-Fi manufacturer may setup Product Families for their Product Ranges, and then specifiy Product Groups within that Family. Product Groups can co-exist in more than one Family at a time.

Classification Codes

Pre-determined MRP set of codes to interact with all of the MRP modules, especially for Purchasing, Sales and Production Control. Each stock item must be linked to a Classification Code. Examples of Codes are

AM Assembly Made-In

AP Assembly Purchased

CP Components

MS Miscellaneous

SM Sheet Metal

LB Labour

There are approx 14 Classification Codes currently "active" within MRP, all of which can be documented / expalined if necessary

Alternative Parts File

Faciltiy to have up to 15 alternative parts to the same part. Useful for superseding stock items, and for intergration in MRP for alternative component stock

Multi-Stock Locations

Facility to support multi-warehousing and up to 100 stores at the same time

Reporting

Stock Evaluation (Part or Product Group), Pareto Analysis (80/20), Obsolescence Reporting and Financial Analysis Summary are just a handful of the facilities available (either PDF or EXCEL)

The Inventory Management module holds the following files

Stock Records

Product Groups

Product Families

Classification Codes

Alternative Parts File

Multi-Stock Locations

Reporting

Stock Records

Each part on the system (whether a Parent or Component) holds a vast amount of information that will be used throughout the MRP application if required. We hold Last Purchase Price, Average Price (weighted or simple), Standard Price (for Standard Costing), and initially 3 Selling Prices for use within Sales Order Processing module. Other standard fields are Minimum Order Qty, Review Levels, Minimum Stock Levels, ABC Classification, Weights, Volumes and Dimensions. Packet Sizes, Economic Batch Qty's (for make or order), Drawing Issue Numbers, and Effectivity Date, are just a few.

Due to the vast number of fields available for each stock item, here are some screenshots to assist in trying to outline a majority of those that are available

Product Groups

Because of the large number of part numbers a client may have, these parts can then be "labelled" into Product Groups. Product Groups could be codes like FG - Finished Goods, CMP - Components, or more detailed breakdown such as VAL - Valves, PTC - Patches and so forth. Product Groups are pre-determined by the client, so you can have as many or as little as you require. Once setup, all reporting can be achieved by Part Number or Product Group. The Purchase Order & Sales Order modules also utilise such profiles.

Product Families

Works a little like Product Groups, but become the overruling "parent" Product Group. For example, a Hi-Fi manufacturer may setup Product Families for their Product Ranges, and then specifiy Product Groups within that Family. Product Groups can co-exist in more than one Family at a time.

Classification Codes

Pre-determined MRP set of codes to interact with all of the MRP modules, especially for Purchasing, Sales and Production Control. Each stock item must be linked to a Classification Code. Examples of Codes are

AM Assembly Made-In

AP Assembly Purchased

CP Components

MS Miscellaneous

SM Sheet Metal

LB Labour

There are approx 14 Classification Codes currently "active" within MRP, all of which can be documented / expalined if necessary

Alternative Parts File

Faciltiy to have up to 15 alternative parts to the same part. Useful for superseding stock items, and for intergration in MRP for alternative component stock

Multi-Stock Locations

Facility to support multi-warehousing and up to 100 stores at the same time

Reporting

Stock Evaluation (Part or Product Group), Pareto Analysis (80/20), Obsolescence Reporting and Financial Analysis Summary are just a handful of the facilities available (either PDF or EXCEL)