Products

MRP-II / ERP

Manufacturing & Distribution

Manufacturing & Distribution

Bill Of Materials

The Bill Of Materials module holds the following files

Structures File (Single & Multi-Level)

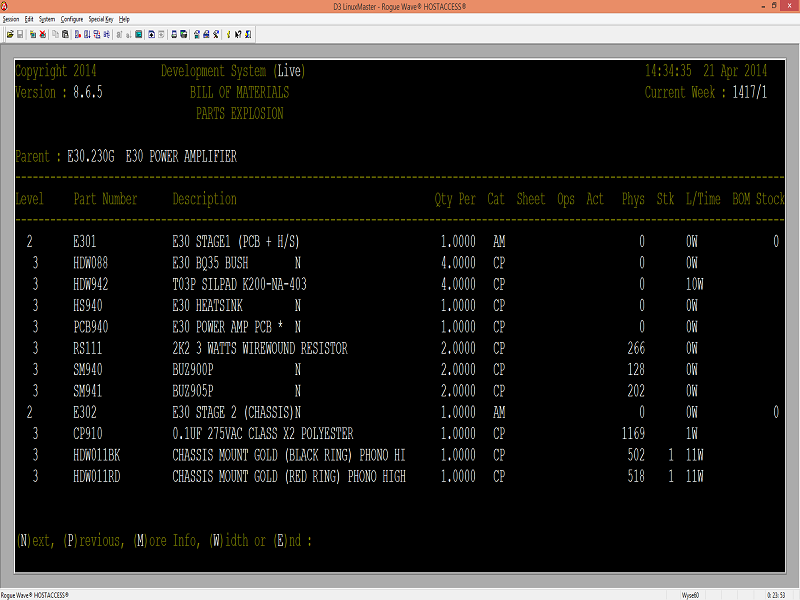

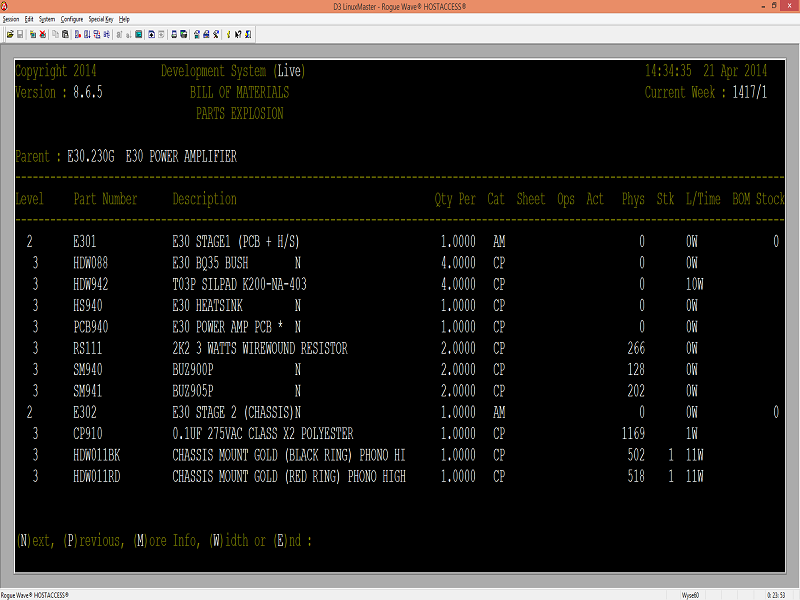

Parts Explosions

Parts Implosions (Where Used)

Assembly Valuation

Mass Re-Costing

Approved Vendor List

Structures File

The Structures File (or BOM) can support Single Level assemblies or Multi-Level (up to a maximum of 99 levels down) with no limitation of items on a BOM. Each Component Part can store, Qty Per (to 4 decimal places), Sequence Level (for PCB's), Back-Fushing, Lead Time Offset and Circuit Reference / Balloon Numbers. Method & Modification issue status is available, thus allowing "change note" control and the facility of holding all previous versions of a BOM.

Parts Explosions / Implosions

Facility to analyse BOM records either from TOP / DOWN, or simply by picking any Component Part and asking what Products it belongs to, either on a Single Level or Multi-Level basis

Assembly Valuation

Produce Assembly Costings based upon current BOM structure, and priced against Last Purchase Price, Average Price or Standard Price

Mass Re-Costing

Facility to mass recost the entire database on a "real" or "ghost" process, at any price held within the Inventory module

Approved Vendor List

Useful tool when Assembly build is sub-contracted out, and you wish to control the "vendors" that the sub-contractor can purchase from. This takes the BOM file and interlinks the Buying Card information for Approved Suppliers, and their relevant Supplier Part Number references.

The Bill Of Materials module holds the following files

Structures File (Single & Multi-Level)

Parts Explosions

Parts Implosions (Where Used)

Assembly Valuation

Mass Re-Costing

Approved Vendor List

Structures File

The Structures File (or BOM) can support Single Level assemblies or Multi-Level (up to a maximum of 99 levels down) with no limitation of items on a BOM. Each Component Part can store, Qty Per (to 4 decimal places), Sequence Level (for PCB's), Back-Fushing, Lead Time Offset and Circuit Reference / Balloon Numbers. Method & Modification issue status is available, thus allowing "change note" control and the facility of holding all previous versions of a BOM.

Parts Explosions / Implosions

Facility to analyse BOM records either from TOP / DOWN, or simply by picking any Component Part and asking what Products it belongs to, either on a Single Level or Multi-Level basis

Assembly Valuation

Produce Assembly Costings based upon current BOM structure, and priced against Last Purchase Price, Average Price or Standard Price

Mass Re-Costing

Facility to mass recost the entire database on a "real" or "ghost" process, at any price held within the Inventory module

Approved Vendor List

Useful tool when Assembly build is sub-contracted out, and you wish to control the "vendors" that the sub-contractor can purchase from. This takes the BOM file and interlinks the Buying Card information for Approved Suppliers, and their relevant Supplier Part Number references.